Fireworks Photo Caption

Occassionally, bad things happen. I recently brought my block to a machine shop for boring and valves. Unfortunately, they did the machine work before hot-tanking it. We found this crack.

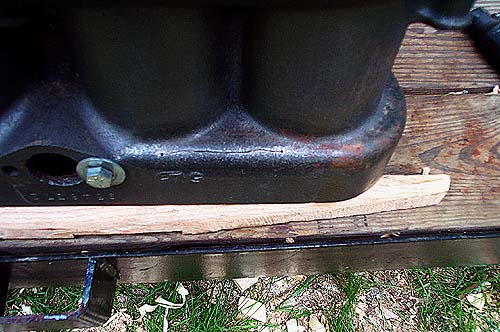

A better picture of the crack.

Cleaned up ready to fix.

Upside down view.

I drilled 2 small holes at either end of the crack to stop the crack from spreading. Stress relief. I then used a real thin cutoff wheel in a dremel tool and "V-d" the crack, enlarging the void to allow solder to flow. Since the water jacket doesn't get too hot, solder was recommended to seal the crack. I found that in an old Ford Owners and Dealer magazine.

Another view of the opened-up crack.

This the block after the solder has been flowed. I used a lot of flux and thoroughly cleaned the crack out with lacquer thinner.

You can see the dremel tool and cutoff wheel in the far right. I filed and sanded down the solder, after applying a few times to ensure I left no air pockets or voids that could leak later.

I used a MAPP torch setup and that really heated the block to accept solder. I left a bolt in the inlet to act as a heat sink.

A file was helpful although it clogged often.

After the soldering job was complete I applied some 2000 Heat Inferno muffler patch. I sanded that to a final finish.

Cast blast is a paint that Donnie Lang sells. It is far better than black or green and doesn't burn off. I have done two engines with no problems.

Finished product. Can you find the crack? I've driven the 2002 National Tour in the mountains of Maryland and a couple thousand miles with no weepage.